California Businesses,

Rethink your Refrigeration

Address potential issues faster and more effectively, while simultaneously improving the operation and efficiency of your refrigeration

"The ability to change temperatures and start defrosts from my laptop or phone is very convenient. Additionally the monitoring and alarms have been a life saver. Not only in protecting tens of thousands of dollars in product but also helping to troubleshoot refrigeration issues that arise as equipment ages. Like all things mechanical, our refrigeration will fail someday. I sleep better knowing that when it does, NRM will sound the alarm to notify us. We use the system daily and have recommended it to others in the business."

— Justin Offenbach, Owner - Golden Gate Meat Co.

NRM has optimized more than 50,000 refrigeration systems

Natl. Beer Distributor

Life Technologies

Baldor Foods Boston

Golden Gate Meat Co.

We help optimize cold spaces of every size

Businesses like yours rely on NRM everyday

Call, Text or Email our CA Advisor, Joe Isaacs, at 916.629.4436 or jisaacs@nrminc.com

What kind of insights will you gain?

You'll have access to a world of valuable operational data that goes far beyond a high temperature alert. You'll be able to see "under the hood" of your system at any time and diagnose the cause of an issue.

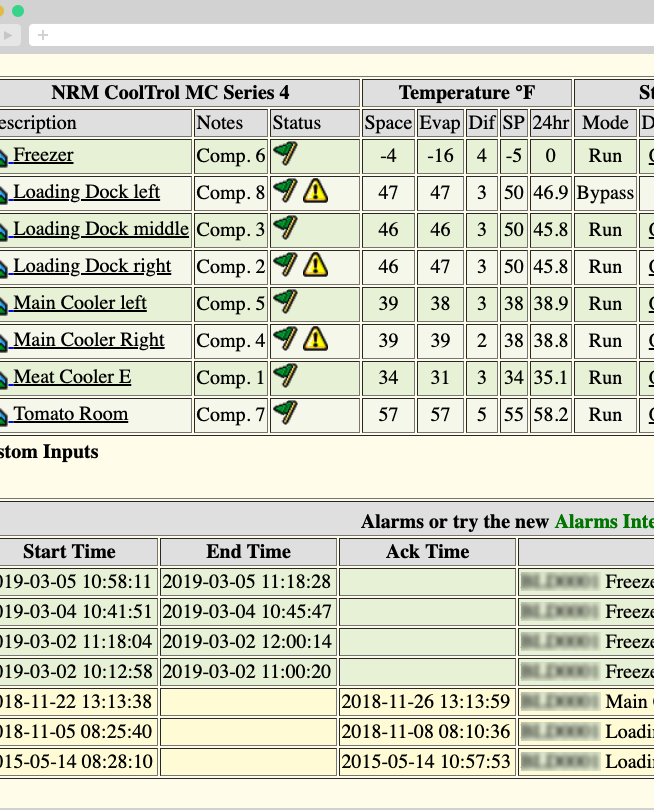

Easy-to-Understand Live Summary Pages

Consult Remote Site Manager’s clear and informative summary pages for a one-look, high-level overview of your system’s operations. You can quickly establish if the system is running optimally and as it should with NRM’s controls through 24-hr. and 7-day runtime averages.

If the monitoring tools catch an operational fault, such as temperatures falling out of range, or the compressor starting excessively, the summary page informs you which system was affected, and when the problem began.

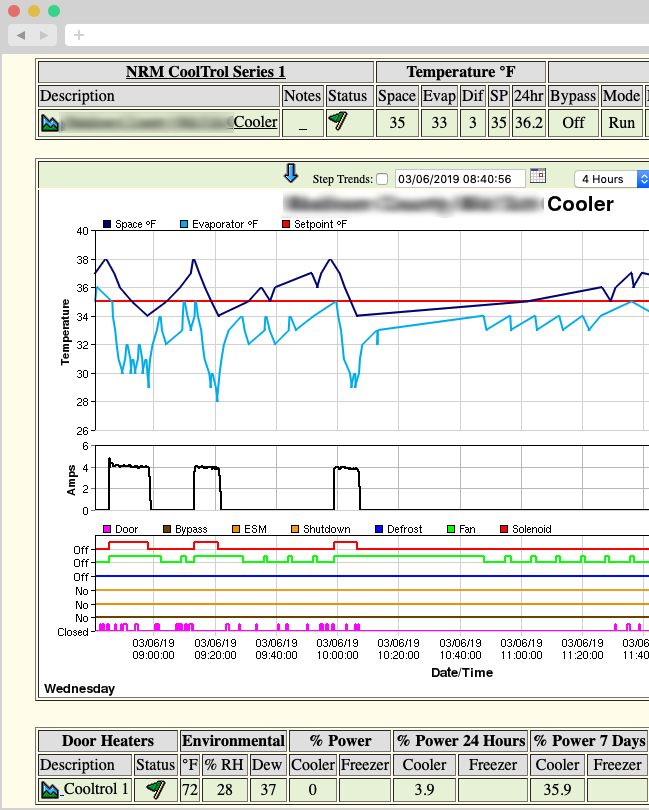

Real-Time Visualized Trends & Diagnostics

The unique diagnostics trends found in Remote Site Manager are invaluable tools that allow you to “peek behind the curtain.” There are a lot of temperature monitoring products out there that will alert you when a space temperature falls out of the desired range, but how many are simultaneously monitoring the source of the issue?

With RSM, you can see if the cause was a door being left open, the compressor failing to respond, an issue with the solenoid inflow, and more.

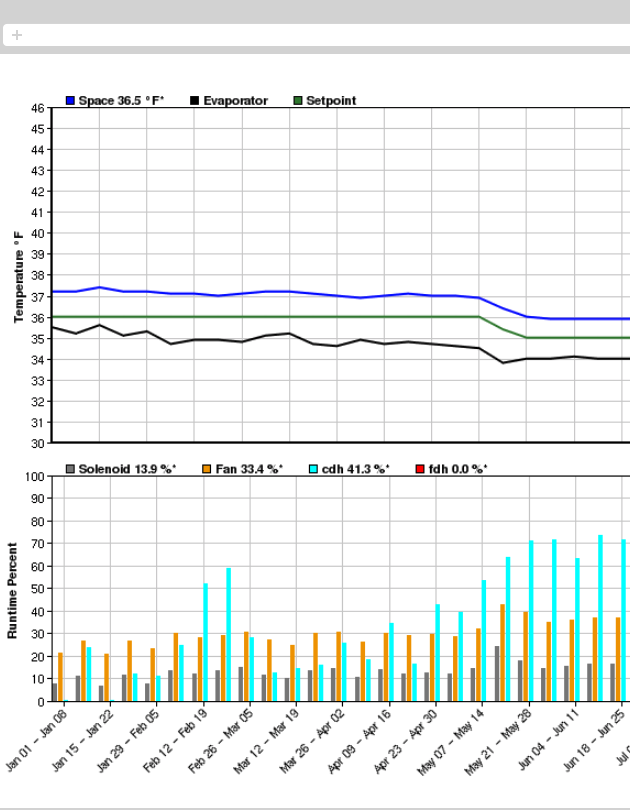

Graphs for M&V and Proof of Savings

Walk-in coolers and freezers can be significant energy hogs, with great ROI and payback opportunities for any sized energy-efficiency projects. Whether you’re reporting on sustainability goals to financial officers and stakeholders, or you’re a small business owner that just wants to be sure the controls are doing for you what was promised, Remote Site Manager offers all of the data and charts you need.

Access and extract ten years’ worth of to-the-second temperature tracking, runtimes, and energy spend.

"We’ve had NRM’s solution for about two years and the annual savings have been great for us. We’ve seen our yearly kWh consumption drop by 33%, which is actually better than what NRM projected. At our current rate of $0.36/kWh, this has translated into nearly $150,000 in realized savings. Needless to say, that has made us very happy customers!"

— Rich - Richmond Wholesale Foods

PGE customers can qualify to get these upgrades for zero out-of-pocket cost.

Between potential incentives funded by PGE and on-bill financing options, it's a no-brainer to get smart controls and equipment monitoring for your cold room or entire cold facility.

Ready to get started? Fill out this short form and we'll be in touch within 24 hours!

If it’s determined that your facility is a good fit for our solution, we’ll work together to plan a full assessment of your refrigeration system to see which optimizations make the most sense. We’ll also look for any incentives your project may qualify for.