Rethink

Refrigeration

Efficiency Oversight Operations Refrigeration

If your business relies on refrigeration, it's for good reason: you have perishable product that needs to be kept at specific temperatures for it to remain safe. NRM can enhance your ability to ensure product integrity while simultaneously improving the system's operational efficiency.

Whether you have a walk-in cooler, walk-in freezer, or large cold facility, NRM can deliver positive, noticeable upgrades that range from reducing your energy usage and costs to providing real-time equipment monitoring through your smartphone.

Reasons you'll love your refrigeration upgrades

A Lower Electric Bill Month After Month

Proven retrofit optimizations like smart controls, equipment upgrades, and better management tools can slash runtimes by 50-70%.

Zero-Finger-Lift Retrofit Installation

NRM controls are installed retrofit to the existing mechanical thermostat, while upgrades like fan motors and in-cooler LEDs are easy to do.

On-Demand Defrost & One-Button Settings

It doesn’t take an advanced degree or hours of training to be able to use NRM’s controls. Most settings and info can be accessed with one button.

Easily Integrated into Existing B/EMS

With its retrofit nature and online connectivity capabilities, the solution can be seamlessly added into an existing management system.

Real-Time Actionable Insights & Alerts

There’s no such thing as a problem that can “wait until Monday” in refrigeration. Get real-time alerts to your device or sent to your technician.

Automated Temperature Tracking

Remove the human-error element from your critical temp. track and recordkeeping. Be better equipped to meet food safety standards.

A Lower Electric Bill Month After Month

Proven retrofit optimizations like smart controls, cooling strategies, and efficient equipment upgrades can slash runtimes by over 50%.

Zero-Finger-Lift Retrofit Installation

NRM controls are installed retrofit to the existing mechanical thermostat, while upgrades like fan motors and in-cooler LEDs are basic replacements.

On-Demand Defrost & One-Button Settings

It doesn’t take an advanced degree or hours of training to be able to use NRM’s controls. Most settings and info can be accessed with one button.

Easily Integrated into Existing B/EMS

With its retrofit nature and online connectivity capabilities, the solution can be seamlessly added into an existing management system.

Real-Time Actionable Insights & Alerts

There’s no such thing as a problem that can “wait until Monday” in refrigeration. Get real-time alerts to your device or sent to your technician.

Automated Historical Temperature Tracking

Remove the human-error element from your critical temp. tracking and recordkeeping. Be better equipped to meet food safety standards.

“I had NRM’s controls installed in the spring and I went the entire summer without a single refrigeration issue. Now that I have the controls, I wish I had gotten them sooner! They’re something I would pay full price for, but the 50% incentive and 0% on-bill financing offered through NHEC was something I couldn’t pass up.”

— Ron, Owner, Patch’s Market

Curious to learn if we can help you specifically? Pick your industry below

We know refrigeration optimization

Optimized

Reduction

Saved

in Businesses

It couldn't be easier to get started on your refrigeration upgrades

NRM has perfected our process over the years to require zero finger-lift on your part. We handle every step from idea to install. Trusted by some of the largest cold companies in the country, and multiple utility-sponsored commercial programs, you can take comfort knowing everything will be managed professionally.

Step 1. System Assessment

An NRM specialist conducts a thorough assessment of your refrigerated space, noting everything from current runtimes, total number of compressors and evaporator fan sets, hardware components used, and more. These findings, along with a copy of your commercial electric bill and a sketch of your cold space, are then sent off to NRM engineers to generate your analysis.

Step 2. Energy Analysis

Next, NRM engineers analyze the data from the assessment. They calculate how many kilowatt hours can likely be reduced from your energy consumption through both reducing runtimes and adding high-efficiency hardware, and in turn, how much money you could potentially save on your electric bill. All calculations can be measured and verified by observing new runtimes.

Step 3. Incentives Application

Following the analysis, NRM applies for the any eligible utility incentives on your behalf. In some cases the utility may offer funds only for certain measures, and in other cases, they offer incentives for the entire refrigeration solution. In addition, some programs offer on-bill financing for zero out-of-pocket cost. NRM works to secure every dollar available for your project.

Step 4. Project Proposal

Once all the info is compiled, NRM presents the project scope to you, and any necessary partners, for your approval. It includes measures to be implemented, and long-term energy savings projections. NRM is also happy to explain the project to any additional staff who will be impacted—such as your refrigeration technician, store manager, or Facilities Director.

Step 5. Project Approval

After reviewing the proposal, the next step is approving both the measures and cost of project. Once approved, NRM works with you to schedule the installation at a time most convenient for you. NRM’s measures and upgrades are typically implemented with zero disruption to your normal business hours, and is completed by licensed professionals.

Step 6. Retrofit Installation

When the installation is complete, NRM provides training for its controls as well as offering 24/7 tech support. But most importantly, all that’s left to do is enjoy the long-term benefits of your new refrigeration management system. Set-it-and-forget-it smart controls deliver energy savings, and the hardware upgrades extend the life of your equipment through less wear and tear.

Comprehensive Performance Benefits for On-Site Operations

Your commercial or industrial refrigeration system is likely managed day-to-day with an “if it’s running, it’s fine” approach, which is not surprising: they’re complex, intimidating machines. So, they typically operate with default settings and as a necessary major expense because your staff are not trained for more.

Your refrigeration does not need to run at 100% full capacity to be effective, though. NRM’s smart controls and operational upgrades adapt the system to run based on your business’ cooling needs (a liquor store has different needs than a meatpacking plant).

Proactively Address Issues to Better Protect Cold Product

Whether in a walk-in cooler or a cold facility, your refrigeration is vital equipment that has to operate properly and without issue. But if it did suffer an underlying problem, who on-site could notice it and then do something about it?

Store managers, hourly employees, and delivery drivers don’t have the technical expertise or the time to diagnose if there’s something going on. And emergency maintenance calls are expensive. NRM’s web-based monitoring acts as a dedicated watchful eye 24/7/365.

"NRM’s state-of-the-art system provides not only efficiencies for the company, it’s also showing us exactly what’s going on under this roof. The facility is broken up into zones so everything at this company is monitored 24/7, 365 days a year. If we do experience an issue, we have access to a 24-hour tech. support line to help us determine what the problems are. I get a notification, and so do the owners and our refrigeration technician so we can take care of the problem spot on."

— George, Facilities Manager, Colony Foods

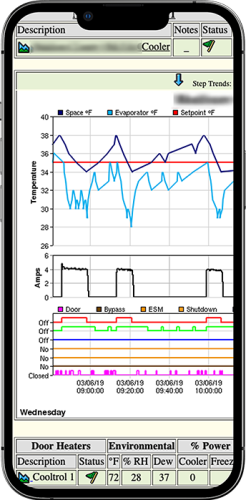

Live System Monitoring

From Anywhere

Gain the ability to manage and control your refrigeration systems from anywhere you have internet access.

Whether you have one cold space or 100, you can improve your oversight and ensure the most optimal performance. No other solution provides this level of data into precisely how your system is running.

We've helped businesses of all types across the country

Rt. 6 Beer & Wine

Marquez Bros. Intl.

Valley Liquors

Stateline Paysaver

Baldor Foods Boston

Life Technologies

Upgrades for your refrigeration system may be eligible for generous incentives from your utility provider that cover 50-100% of the up-front project cost.

But incentive dollars are awarded first-come, first-served so act now!

Most common questions we hear

How can NRM's solution save so much energy?

Refrigeration and HVAC equipment are sized for THE HOTTEST DAYS of the year, and they always add a safety factor in case more is needed. But the “hottest days” only happen 20-30 times per year, which means all systems are oversized for the other 330~ days. The CoolTrol® system manages all the loads to take advantage of the oversizing, and turns off loads that don’t need to be on all the time. It also manages defrost more closely to what is needed. Some facilities have very big cold rooms so they add redundant systems meaning that capacity can sometimes be 2-4x of what is needed on average days.

My refrigeration tech says it's not safe to turn off my evaporator fans. Is that true?

In an unsafe manner, yes. But with NRM’s solution, it is perfectly safe. Implemented in over 50,000 systems to-date, the new controls keep fans running when refrigeration is ON and only cycles them OFF and whenever refrigeration is OFF. Every running fan motor generates heat and the new system run time when air movement is not necessary. Why keep the heaters running once temperature set point is reached?

What kind of guarantee can you provide me that these savings are real?

NRM has earned the utility’s trust and confidence, which is the greatest guarantee we can offer. In some programs, NRM has been providing solutions since 1997 with the local utility company’s backing. We would not continue to win these contracts year over year if we didn’t produce deliver the projected savings.

Why is the utility company paying me money to use LESS energy?

Most states have adopted laws to get citizens and companies to use less energy as it is more economical to encourage consumers to use less energy through incentives than to build a new power plant which no one wants near them. Utilities are tasked with collecting a fee on your utility bill based on usage. It may be a line item shown as “public benefit charge” or “energy conservation charge”. This money accumulates and is used to fund the incentives that pay for energy efficiency optimizations.

Since it is available for all ratepayers, it is a great way to fund energy efficiency programs that give capacity back to the electrical grid while also reducing your commercial electric bill. So, it’s a smart investment to participate in the programs and to take advantage of the incentives to get some of your money back through upgrades to your own equipment.

The money isn’t free, but it will contribute toward qualified energy efficiency projects. It’s a great way to make a difference to your bottom line.

How much incentive do I qualify for?

It really depends on how much energy a project can save… just think of it as the utility buying capacity from you to prevent overtaxing the energy grid. The power you save now becomes available to new customers. To find out what you can get, we recommend a no cost assessment of your current system that will enable us to calculate savings that we then present to your utility company who allots the amount they will pay for your capacity. If your systems already are considered partially or totally energy efficient, there may be little or no opportunity for reducing energy or qualifying for an incentive.

What level of technical proficiency is required to use CoolTrol®?

CoolTrol® is designed specifically for you, the end user. It is equipped with software developed by NRM and is designed to intelligently operate equipment at optimum energy efficiency. It becomes your new refrigeration thermostat that takes advantage of every opportunity for saving energy. It has many user-friendly features and a superior user interface compared to traditional refrigeration thermostats that are primarily designed for technicians, not end users.