NRM Success Story

Baldor Foods Boston

Chelsea, MA

Baldor Foods Boston not only greatly improved the efficiency of their refrigeration system, but they also gained new capabilities to better manage its operation. NRM provided a full-service solution they now can't live without.

What They Needed

Baldor Boston, a leading produce distribution company in the area, was in the market for one, simple solution that could remedy their multiple operational issues. While many of the systems on the corporate-office side of their business had been streamlined to better rely on data and cloud-based tools, their actual facility was falling woefully behind.

Their refrigerated spaces were wasting energy through redundancies, they experienced fluctuations in space temperatures without being able to pinpoint the causes, and the facility had already absorbed the cost of losing a compressor once before. It was most important to them that whichever solution they went with, user-friendliness and accessibility were two of its main offerings. On top of that, the solution needed to aid Baldor staff in their dedication to top food safety practices, improving temperature tracking and regulatory adherence.

If troubleshooting could be enhanced, all the better.

WHAT NRM PROVIDED

Starting with an on-site assessment of their current energy consumption, equipment health, component functionality, and management tools, NRM immediately delivered the peace of mind and simplicity Baldor was after. For every feature they wanted, NRM was able to succinctly describe how each could be achieved within our optimization solution. Once the project scope was approved, and work began, Baldor Boston was thrilled that every part of the integration was handled by licensed in-house NRM employees—from the engineering analysis to the hardware installation, to the controls and software training, to the post support.

The custom solution built for Baldor was crafted around the Remote Site Manager platform, which empowered their General Manager to track space temperatures at any given time, create adaptive cooling schedules based on delivery times and holding temperature requirements, set mobile alerts if the equipment experiences a mechanical issue during off-hours, and access a web dashboard that displays all of their cold rooms from a single hub.

Two unexpected benefits of integrating NRM’s solution that Baldor appreciated: a happier workforce due to a quieter environment (the industrial-sized fans previously operated with 100% runtimes), and more productive technician visits due to the visual diagnostics data.

Industry

Food Distribution

Location

Chelsea, MA

Cold Rooms

- 1 Walk-in Freezer

- 3 Loading Docks

- 3 Walk-in Coolers

- 1 Tomato Room

Implemented Measures

- CoolTrol refrigeration controls

- Remote Site Manager

Utility Incentive

70% of Project Cost

Annual Energy Savings

122,300 kWh

Annual Dollar Savings

$21,000

"The monitoring features have been a life saver. One of our compressors suffered a blown fuse, and it would have gone undetected prior to NRM’s intervention because our space temperatures read normal and you obviously can’t hear or easily see a blown fuse. But it was quickly detected, I was alerted, I contacted our technician, and he was able to diagnose the exact problem and fix it on the first visit."

— Glenn, General Manager

Avoid food safety crises with a wealth of operational data and proactive insights

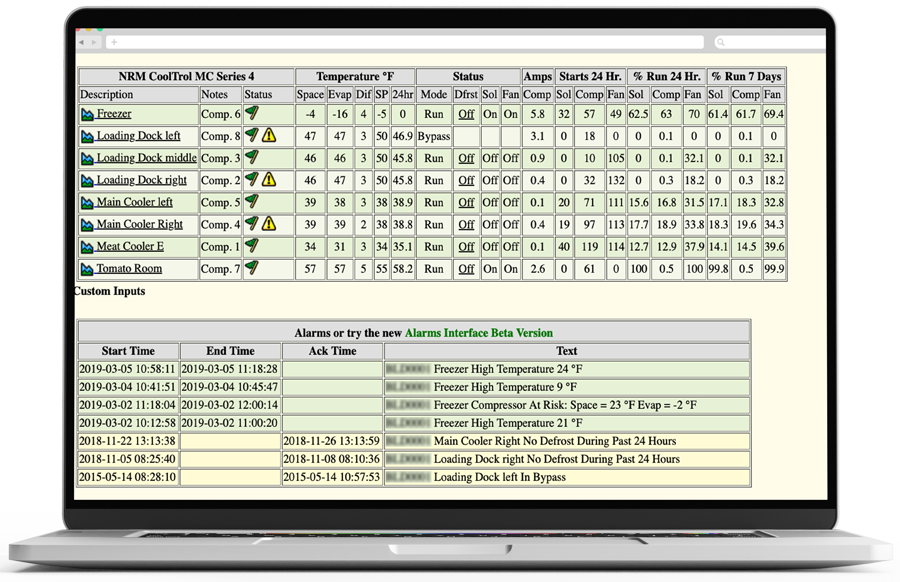

Whether you have 1 cold space in a single school kitchen, or 100 cold spaces spread across an entire district, our live summary page gives you an immediate overview of all your cooling activity.

Quickly consult current and 7-day runtimes, cooling status, temperature settings, and address any alarms that have been triggered.

Consider the amount of time and effort you’d save by having critical operational info all conveniently in one place.

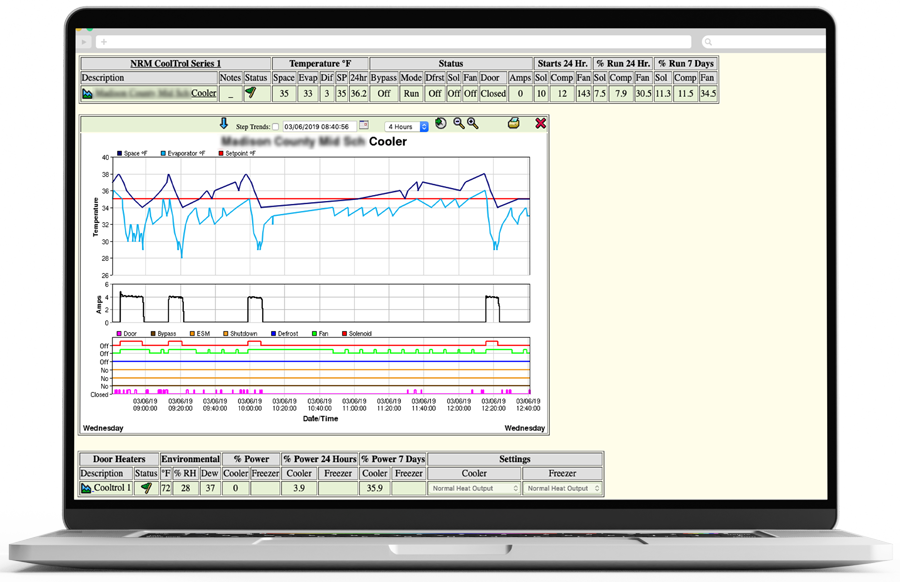

Arm yourself with powerful and unique visual diagnostics graphs to pinpoint exactly when and where an operating issue arises. Troubleshooting becomes more efficient and effective, helping to ensure the issue is resolved on the first technician visit.

The graphs show important but often overlooked components such as amperages, compressor cycles, the solenoid valve, and things like whether a door is open or not.

The monitoring platform offers transparent runtime and temperature data that provide the measurement and verification proof for accurate recordkeeping.

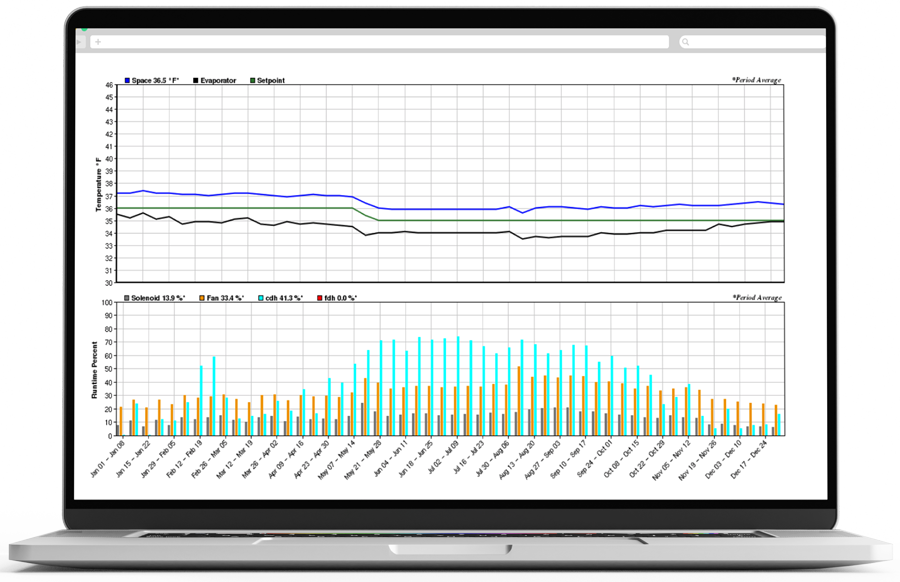

These graphs also allow you to actually see how much less energy your refrigeration system is using. While also tracking that safe temperatures are always met.

Store up to 10 years of operational logs that take the human-error component out of tracking temperatures.

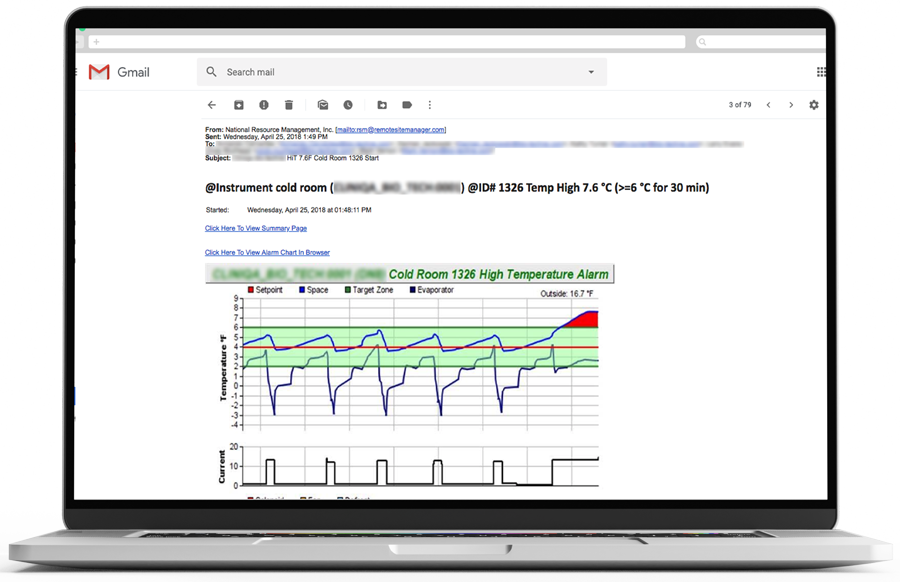

Going beyond a high temperature alert — which occurs only after an issue has already disrupted operations — NRM’s platform provides a suite of early detection notifications to help you be more proactive with troubleshooting.

For example, a compressor that’s short cycling will still likely be able to cool the space, but it’s dangerous, unnoticed overuse could lead to a critical system failure, jeopardizing the entire cooler’s worth of food.