Resources & Knowledge Center

Food Safety Information

The importance of refrigeration food safety in the cold chain

The industrial cold chain is the backbone of global food safety, ensuring that perishable products maintain their quality and safety from production to consumption. At the heart of this complex system lies industrial refrigeration—the single most crucial element in maintaining temperature integrity throughout the supply chain. When refrigeration systems fail or operate inefficiently, the consequences can be devastating: spoiled products, financial losses, regulatory penalties, and most importantly, potential health risks to consumers.

This page explores the critical components of the cold chain and the regulations that govern food safety, emphasizing why maintaining optimal refrigeration systems is not just beneficial but essential for the food industry.

Food Storage: The Foundation of Cold Chain Integrity

The storage phase of the cold chain serves as the anchor point for maintaining food safety and quality. Proper refrigeration at storage facilities prevents bacterial growth, preserves nutritional value, and extends shelf life, serving as the first line of defense against foodborne illness outbreaks. Temperature consistency in storage facilities is not merely a quality concern but a fundamental safety requirement that protects public health and supports regulatory compliance.

- Temperature zonation is essential for optimal storage conditions. Different food products require specific temperature ranges to maximize shelf life and maintain safety. According to the International Association for Food Protection, improper temperature zonation can reduce shelf life by up to 50% and increase food safety risks significantly.

- Modern refrigeration monitoring systems provide real-time alerts before critical thresholds are breached. The Food and Drug Administration (FDA) reports that facilities implementing continuous monitoring systems experience 63% fewer temperature excursions compared to those relying on manual checks. As noted in a National Resource Management blog post, “The ability to detect temperature deviations before they become critical helps facilities avoid costly product losses and potential safety issues.”

- Proper air circulation and humidity control are equally important as temperature management. Research published in the Journal of Food Science (2022) found that fluctuations in humidity levels can accelerate spoilage even when temperatures remain within acceptable ranges. Industrial refrigeration systems must maintain optimal air circulation to prevent “hot spots” within storage areas.

- Backup power systems for refrigeration units are non-negotiable components of food safety plans. The International Association of Refrigerated Warehouses estimates that 40% of food loss in storage facilities occurs during power outages. Facilities with redundant power systems experience 87% less product loss during utility interruptions.

- Regular maintenance of refrigeration equipment significantly extends operational life and ensures consistent performance. National Resource Management researchers found that preventive maintenance programs can reduce emergency refrigeration repairs by 70% and extend equipment lifespan by up to 40%.

If storage refrigeration systems fail, the consequences can be immediate and severe. A single 24-hour cooling failure at a major distribution center can result in the loss of millions of dollars in inventory, particularly for high-value proteins and dairy products. In 2023, a refrigeration system failure at a Midwest distribution center led to the disposal of over $3.2 million in perishable products when temperatures rose above safe levels for just 8 hours. Beyond financial losses, compromised storage conditions can allow dangerous pathogens like Listeria monocytogenes to multiply to dangerous levels, potentially affecting thousands of consumers before detection.

Food Transportation: Maintaining the Integrity of the Cold Chain in Motion

The transportation phase represents the most vulnerable link in the cold chain, where temperature control faces unique challenges. While products are in transit, they encounter variable environments, multiple handling points, and potential equipment failures that can compromise safety and quality. Maintaining refrigeration integrity during transportation requires specialized equipment, careful planning, and continuous monitoring to prevent temperature excursions that could lead to product deterioration or safety hazards.

- Pre-cooling vehicles before loading is a critical step that is often overlooked. Research from the Transportation Research Board (2021) shows that properly pre-cooled refrigerated trucks maintain target temperatures 43% more consistently than those loaded without pre-cooling. This simple step significantly reduces the strain on refrigeration systems during transport.

- Reefer unit maintenance is essential for reliable temperature control during transit. According to the Global Cold Chain Alliance, approximately 30% of temperature excursions during transport can be attributed to poorly maintained refrigeration units. As highlighted in a National Resource Management case study, “Regular maintenance of transport refrigeration systems can reduce breakdown rates by up to 65% and extend equipment life by 3-5 years.”

- Advanced multi-temperature zone transport vehicles allow for simultaneous transportation of products with different temperature requirements. The International Journal of Refrigeration (2020) reports that multi-zone vehicles can improve logistics efficiency by up to 35% while maintaining product integrity for diverse cargo types.

- Loading practices significantly impact refrigeration efficiency during transport. Improper loading that blocks air circulation can create temperature variations of up to 15°F within the same trailer. The Food Safety Modernization Act (FSMA) transportation rules specifically address loading configurations to ensure proper air circulation throughout the cargo area.

- Thermal blankets and insulation materials provide an additional layer of protection during loading/unloading. Research published in the Journal of Food Protection demonstrates that properly used thermal blankets can maintain safe temperatures for up to 45 minutes during unloading procedures, reducing exposure to ambient temperatures.

Transportation refrigeration failures can lead to rapid product deterioration and significant financial losses. In 2022, a refrigeration system malfunction during a cross-country shipment of fresh seafood resulted in a total loss valued at $280,000 when temperatures rose above safe levels for just six hours. Beyond the immediate financial impact, transportation failures can trigger widespread product recalls if temperature-abused products reach retail locations. The Food Marketing Institute estimates that the average cost of a food recall exceeds $10 million when accounting for direct costs, legal liability, and brand damage.

Additionally, transportation failures that allow pathogens to multiply can lead to widely dispersed illness outbreaks that are difficult to trace, potentially affecting consumers across multiple states.

Temperature Monitoring: The Vigilant Guardian of the Cold Chain

Temperature monitoring serves as the nervous system of the cold chain, providing critical data and alerts that enable proactive management of refrigeration systems. Without robust monitoring, even the most advanced refrigeration equipment can fail silently, potentially compromising food safety without detection until it’s too late. Modern monitoring systems not only track current conditions but also identify trends and patterns that can predict potential failures before they occur.

- Continuous temperature monitoring is superior to periodic manual checks. Research published in Food Control (2023) found that facilities using continuous monitoring systems detected 97% of temperature excursions compared to only 46% detection with manual checks. National Resource Management notes that “The shift from periodic to continuous monitoring represents one of the most significant advancements in refrigeration safety in recent decades.”

- Remote monitoring capabilities allow for immediate corrective actions. According to the Food Safety Magazine (2022), facilities with remote monitoring capabilities respond to temperature excursions an average of 3.5 hours faster than those relying on on-site personnel, significantly reducing the risk of product loss.

- Advanced monitoring systems can predict equipment failures before they occur. Predictive analytics applied to refrigeration monitoring data can identify patterns indicative of impending failures with up to 85% accuracy, according to research from the International Institute of Refrigeration.

- Temperature mapping of storage areas identifies hot spots and circulation issues. The FDA recommends comprehensive temperature mapping of storage facilities to identify areas where circulation may be compromised. Studies show that temperature variations of up to 8°F can exist within facilities that appear to maintain consistent temperatures based on limited monitoring points.

- Automated documentation ensures compliance with regulatory requirements. The FSMA requires detailed temperature records throughout the cold chain. Automated systems not only improve accuracy but also reduce labor costs associated with manual record-keeping by up to 70%.

Temperature monitoring failures have led to some of the most costly incidents in food safety history. Without proper monitoring, a refrigeration system failure at a major distribution center went undetected for nearly 18 hours, resulting in the loss of $4.7 million in inventory that had to be destroyed. In 2021, a pharmaceutical company faced a $12 million loss when temperature-sensitive vaccines were compromised due to a monitoring system failure that didn’t alert staff to a gradually failing refrigeration unit. Beyond financial losses, monitoring failures can allow contaminated products to reach consumers, potentially leading to serious illness outbreaks.

The Centers for Disease Control and Prevention estimates that approximately 48 million Americans experience foodborne illnesses annually, with improper temperature control being a primary contributing factor.

The Costs of Cold Chain Disruption

The financial implications of cold chain failures extend far beyond the immediate value of lost product. When refrigeration systems fail, the associated costs can be staggering:

- Direct product losses typically range from $50,000 to $5 million per incident depending on the facility size and products affected. High-value proteins and pharmaceuticals represent the greatest financial risk per cubic foot of storage.

- Equipment repair or replacement costs can exceed $100,000 for major refrigeration system failures. Emergency repairs typically cost 3-5 times more than scheduled maintenance, according to the International Institute of Refrigeration.

- Business interruption losses often exceed the direct product losses, especially for facilities that serve as critical distribution points. The Food Marketing Institute estimates that associated business interruption costs can reach $25,000 per hour for large distribution centers.

- Regulatory fines and penalties for temperature violations can range from $10,000 to $500,000 depending on the severity and whether public health was endangered. The FDA has increased inspection frequency and penalties for cold chain violations since the implementation of FSMA.

- Legal liability and litigation costs following foodborne illness outbreaks can reach into the millions. A single multi-state outbreak linked to temperature-abused product can result in settlements exceeding $25 million.

- Brand damage and lost customer relationships often represent the most significant long-term costs. According to a study by the Grocery Manufacturers Association, companies experience an average 22% decline in share value following major food safety incidents.

Food Safety Laws and Regulations

The regulatory landscape governing food safety and the cold chain has evolved significantly in recent years, with more stringent requirements for temperature control and monitoring:

- The Food Safety Modernization Act (FSMA) represents the most comprehensive reform of food safety laws in over 70 years, shifting the focus from responding to contamination to preventing it. The FSMA Preventive Controls for Human Food Rule established requirements for hazard analysis and risk-based preventive controls, including specific provisions for temperature control.

- The FSMA Sanitary Transportation Rule specifically addresses temperature control during transportation. The rule requires carriers to ensure that vehicles and transportation equipment are designed, maintained, and equipped to prevent food from becoming unsafe during transportation.

- The FDA Food Code provides model regulations for food retail and service establishments. The Food Code includes specific temperature requirements for various food categories and has been adopted by most states as the basis for their food safety regulations.

- The Hazard Analysis Critical Control Point (HACCP) system has been mandated for various food industries. The HACCP principles identify temperature as a critical control point for many food products, requiring specific monitoring and documentation.

- The Global Food Safety Initiative (GFSI) has established benchmarking requirements for food safety schemes worldwide. GFSI certification is increasingly required by major retailers and includes specific provisions for temperature control throughout the supply chain.

Common Foodborne Illnesses Associated with Cold Chain Failures

Temperature abuse in the cold chain can lead to rapid growth of pathogenic microorganisms, resulting in serious foodborne illnesses:

- Listeria monocytogenes thrives in refrigeration temperatures and can cause listeriosis, a serious infection with a mortality rate of approximately 20% in vulnerable populations.

- Clostridium perfringens spores can survive cooking and multiply rapidly when cooked foods are improperly cooled, causing intense abdominal pain and diarrhea.

- Bacillus cereus produces heat-stable toxins in temperature-abused foods, leading to two types of illness: a diarrheal type and a vomiting type.

- Salmonella multiplication accelerates significantly when temperatures rise above 40°F, causing salmonellosis characterized by fever, abdominal cramps, and diarrhea.

- Staphylococcus aureus produces heat-stable toxins when allowed to multiply in temperature-abused foods, causing rapid onset of severe nausea, vomiting, and abdominal cramps.

- Escherichia coli O157:H7 and other Shiga toxin-producing E. coli can cause severe illness even at relatively low concentrations, which can be reached quickly in temperature-abused products.

- Vibrio parahaemolyticus and other Vibrio species can multiply rapidly in seafood when temperature control is inadequate, causing gastrointestinal illness.

What It All Means for Your Business

The industrial cold chain represents a complex system where refrigeration serves as the critical foundation for food safety and quality. From storage facilities to transportation vehicles and comprehensive monitoring systems, every component plays an essential role in maintaining temperature integrity. When any part of this system fails, the consequences extend far beyond immediate product losses to include regulatory penalties, potential legal liability, and most importantly, public health risks.

The cost of disrupting the cold chain is simply too great to leave to chance. Investment in robust refrigeration systems, comprehensive monitoring capabilities, and emergency response planning represents a fraction of the potential losses associated with a major cold chain failure. As regulatory requirements continue to evolve and consumer expectations for food safety rise, maintaining refrigeration system integrity has never been more crucial.

For food processors, distributors, and retailers, the message is clear: refrigeration is not merely equipment—it’s the lynchpin of food safety, regulatory compliance, and business continuity. Preparing for refrigeration emergencies is not an optional precaution but an essential component of responsible food safety management.

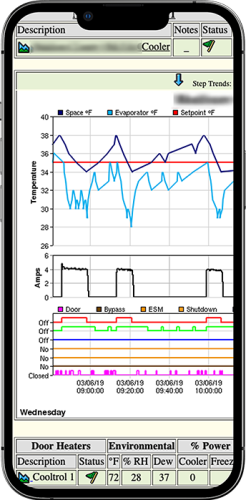

Live System Monitoring

From Anywhere

Gain the ability to manage and control your refrigeration systems from anywhere you have internet access.

Whether you have one cold space or 100, you can improve your oversight and ensure the most optimal performance. No other solution provides this level of data into precisely how your system is running.