NRM Success Story

Marquez Brothers International

Multiple Locations Across USA

Marquez Brothers International not only greatly improved the efficiency of their refrigeration system, but they also gained capabilities to better manage its operation. NRM provided a full-service solution they now can't live without.

What They Needed

Marquez Brothers International has been producing, distributing, and selling beloved cheese, dairy, and meat products across the country since 1981. While they have a network of dedicated and trusted distributors, they also have their own large, cold storage facilities. After all, meat and dairy products need to be stored safely at very specific temperature ranges prior to being stocked on a shelf in a grocery store.

Initially, being able to manage the refrigeration systems from a centralized location was the most important qualification in their search for a solution. With facilities up and down California, and as far as Las Vegas, Nevada and Phoenix, Arizona, it was obviously impossible for corporate-level managers to be at every site at once.

Saving energy was icing on the cake, and so when NRM’s analysis showed their solution could slash over one million kWh from Marquez Brothers’ facilities’ energy consumption on top of a management system, choosing NRM was an easy decision.

WHAT NRM PROVIDED

NRM was able to improve the performance of the industrial refrigeration systems across seven different facilities for Marquez Brothers International. These unique measures included installing smart system controls, replacing existing motors with high-efficiency EC versions, cloud-based equipment monitoring, and smart electric defrost that drastically reduces the occurrence of iced up coils.

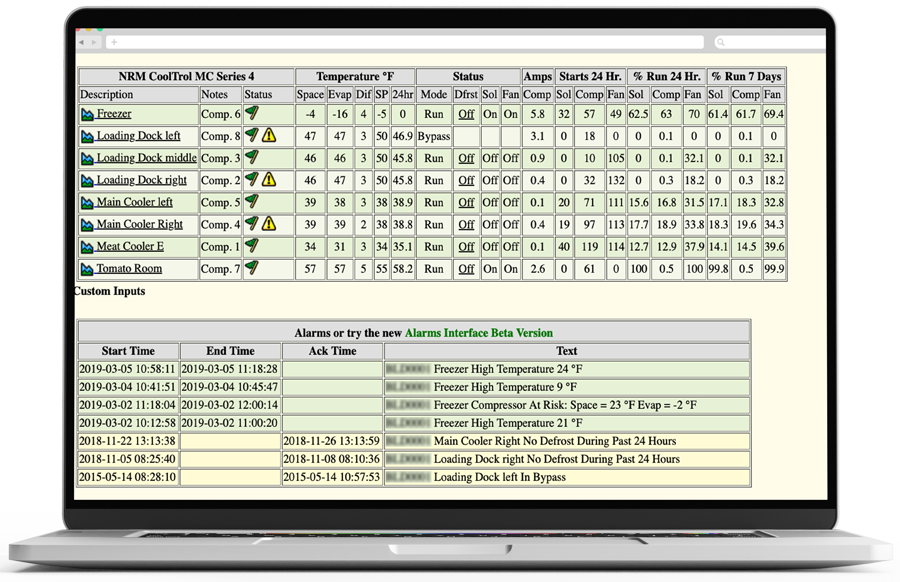

The solution also provides crucial performance data that they simply had no way of accessing before. Through the Remote Site Manager™ dashboard, they’re able to view the operating statistics of how their systems are running in real-time.

They can solve minor, previously undetected issues before they become catastrophic system failures. When it comes to the safety of perishables, any problem is a race against the clock. This allows their technicians to go from reactive to proactive in handling refrigeration issues.

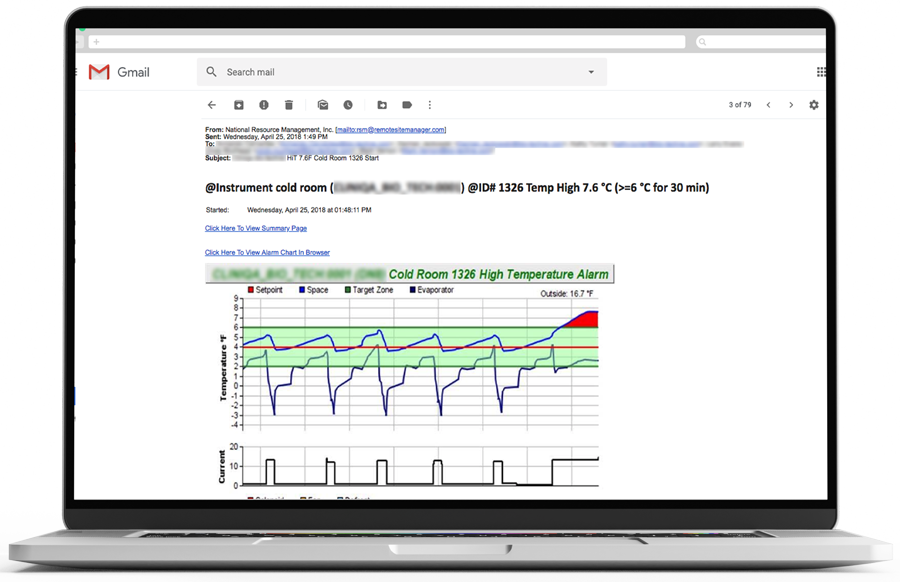

Enhancing that product safety even more, Remote Site Manager™ delivers instant alerts via email or text message. It also tracks, logs, and collates temperature and operational data for any kind of food regulatory requirements.

It has essentially removed the human-error element from product safety.

Industry

Food Distribution

Locations

- California (5)

- Las Vegas, NV

- Phoenix, AZ

Implemented Measures

- CoolTrol refrigeration controls

- Remote Site Manager

- Anti-Sweat Door Heater controls

- EC Motor Upgrades

Utility Incentive

70% of Project Cost

Annual Energy Savings

1,050,000 kWh (combined)

Annual Dollar Savings

$150,000 (combined)

Avoid food safety crises with a wealth of operational data and proactive insights

Whether you have 1 cold space in a single school kitchen, or 100 cold spaces spread across an entire district, our live summary page gives you an immediate overview of all your cooling activity.

Quickly consult current and 7-day runtimes, cooling status, temperature settings, and address any alarms that have been triggered.

Consider the amount of time and effort you’d save by having critical operational info all conveniently in one place.

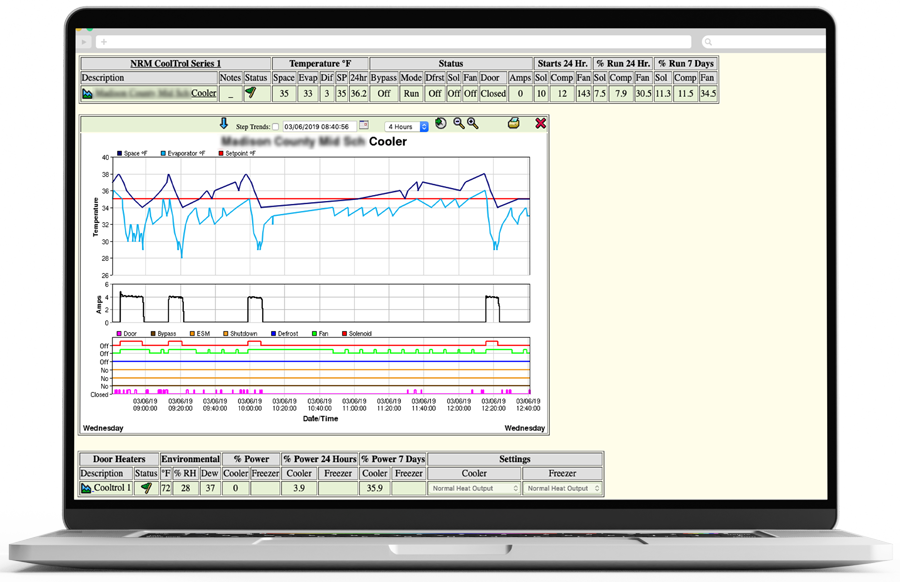

Arm yourself with powerful and unique visual diagnostics graphs to pinpoint exactly when and where an operating issue arises. Troubleshooting becomes more efficient and effective, helping to ensure the issue is resolved on the first technician visit.

The graphs show important but often overlooked components such as amperages, compressor cycles, the solenoid valve, and things like whether a door is open or not.

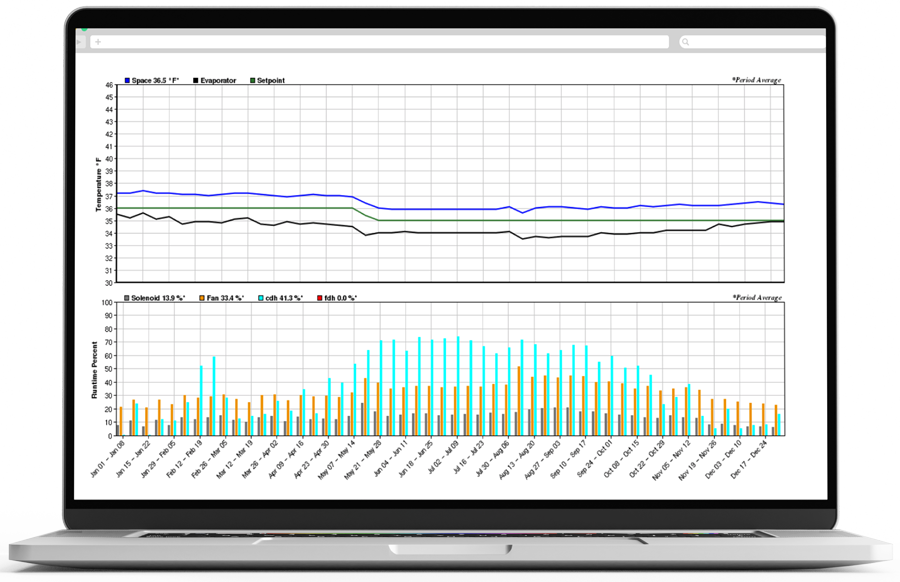

The monitoring platform offers transparent runtime and temperature data that provide the measurement and verification proof for accurate recordkeeping.

These graphs also allow you to actually see how much less energy your refrigeration system is using. While also tracking that safe temperatures are always met.

Store up to 10 years of operational logs that take the human-error component out of tracking temperatures.

Going beyond a high temperature alert — which occurs only after an issue has already disrupted operations — NRM’s platform provides a suite of early detection notifications to help you be more proactive with troubleshooting.

For example, a compressor that’s short cycling will still likely be able to cool the space, but it’s dangerous, unnoticed overuse could lead to a critical system failure, jeopardizing the entire cooler’s worth of food.