In most walk-in coolers and freezers, the evaporator fans run 24 hours a day, 365 days a year, at full speed. Those fans are not only consuming energy the whole time, they are also generating heat, and the constant swirling of the air picks up even more heat from surrounding lights, walls, open doors, and people.

This makes evaporator fans an obvious place to look for energy savings in commercial refrigeration, and today there are a number of gadgets, gizmos, and black boxes on the market that try to reduce the speed or run time of evaporator fans.

But is it really a good idea to turn off or slow down those fans? Why do they run all the time, anyway? Why not just turn them off when the thermostat is satisfied?

The answer isn’t always simple, but the first step is understanding the three major risks that are offset through constant, full-speed fan operation. Only if we can reliably solve for all three potential dangers, can we safely change the operation of the evaporator fans.

Risk 1: Incomplete evaporation.

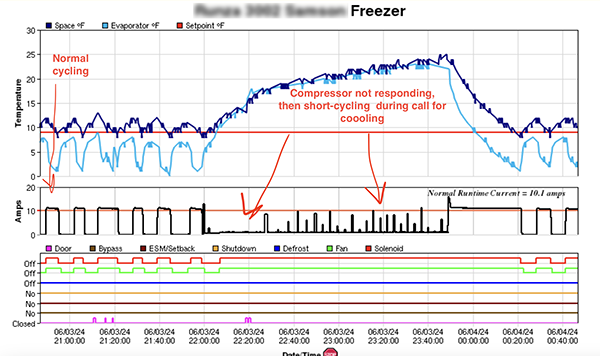

Your walk-in cooler or freezer is an integrated system. The physics behind evaporative cooling requires a certain amount of airflow across the cooling coil in order to work properly. If the air moving across the coil is slowed (or stopped), there is a risk of incomplete evaporation of the refrigerant, which is not only bad for the efficiency of the system but also potentially really bad for the compressor. And because failure to harvest all of the cooling leads to higher run times on the compressor, a poorly-implemented controls or sensing scheme could actually end up costing a lot more energy than was saved by controlling the fans!

Risk 2: Defrost problems.

Part of the function of the fans is to equalize the temperature between the cooling coil and the air inside of the cooler or freezer. If the fans are not moving the right amount of air across the coil at the right times, the cooling coil ends up much colder than the air temperature. Just like a cold can of soda on a warm day, that coil will attract condensation out of the warmer surrounding air, except the condensation form as ice. And if that ice builds up, watch out! Frozen coils are a source of many types of refrigeration problems. And once again, running a cooler with a frozen coil causes even higher energy use, which takes a bigger chunk out of profits than simply leaving the fans on all the time.

Risk 3: “Stratification” and air movement.

Most people will remember from science class that warm, light air rises and cool, denser air sinks. Additionally, most coolers and freezers have one side that gets warmer faster than the other (often the side closest to doors, lights, and other sources of heat). If you have a thermostat in the back of the cooler, and it doesn’t know that the front of the cooler is getting warm, then you may not be meeting food safety or product quality requirements. Warm product is not a good way to save energy!

When taking a look at these dangers, it is easy to see why many people are skeptical about energy-saving evaporator fan controls. Is there are any reward or is it all risk? And the people proposing these energy-saving measures may have little or no real experience with refrigeration. If your cooler or freezer starts running warm on a weekend or after-hours, who is going to answer the phone? Will it be someone with the competence to troubleshoot refrigeration?

The good news is that there are solutions on the market that work, and that have solved these problems. And if it’s done right, evaporator fan controls can definitely save significant energy. A typical convenience store walk-in cooler with 6 fans could save almost 6,000 kilowatt-hours per year, which could prevent $1,000 or more in annual profit loss.

In our next post, we will talk about what to look for, to make sure a fan-control system is going to improve your business, your cooler operation, and your profitability, instead of making things worse.