As we throttle toward the end of this decade and into the future, the Internet of Things (IoT) continues to become more and more ubiquitous in our daily lives. On smaller scales, we see it in our homes with products that now merge thermostats with home security, or allow us to order items from Amazon through voice-activation. On a massive scale, we see it in the near-full automation of some global supply chains. And right in the middle of those ends of the spectrum, we’re starting to see it become standard practice in the one place we spend most of our time: the workplace.

In particular, the HVAC/Refrigeration industries are beginning to catch up to the times and see the benefit of automating the operations that they can. Lighting, heating systems, and refrigeration systems can all stand to be improved either through incorporation into a Building Management System or equipped with their own specific controls and automation tools.

There are a bevy of reasons why if your building doesn’t already have something in place, you should consider looking into it.

Operational efficiency

In a nutshell, by removing the human element from many of your processes, your equipment will run better, more efficiently, and you’ll recoup some of the time spent on repeatable tasks that should be automated.

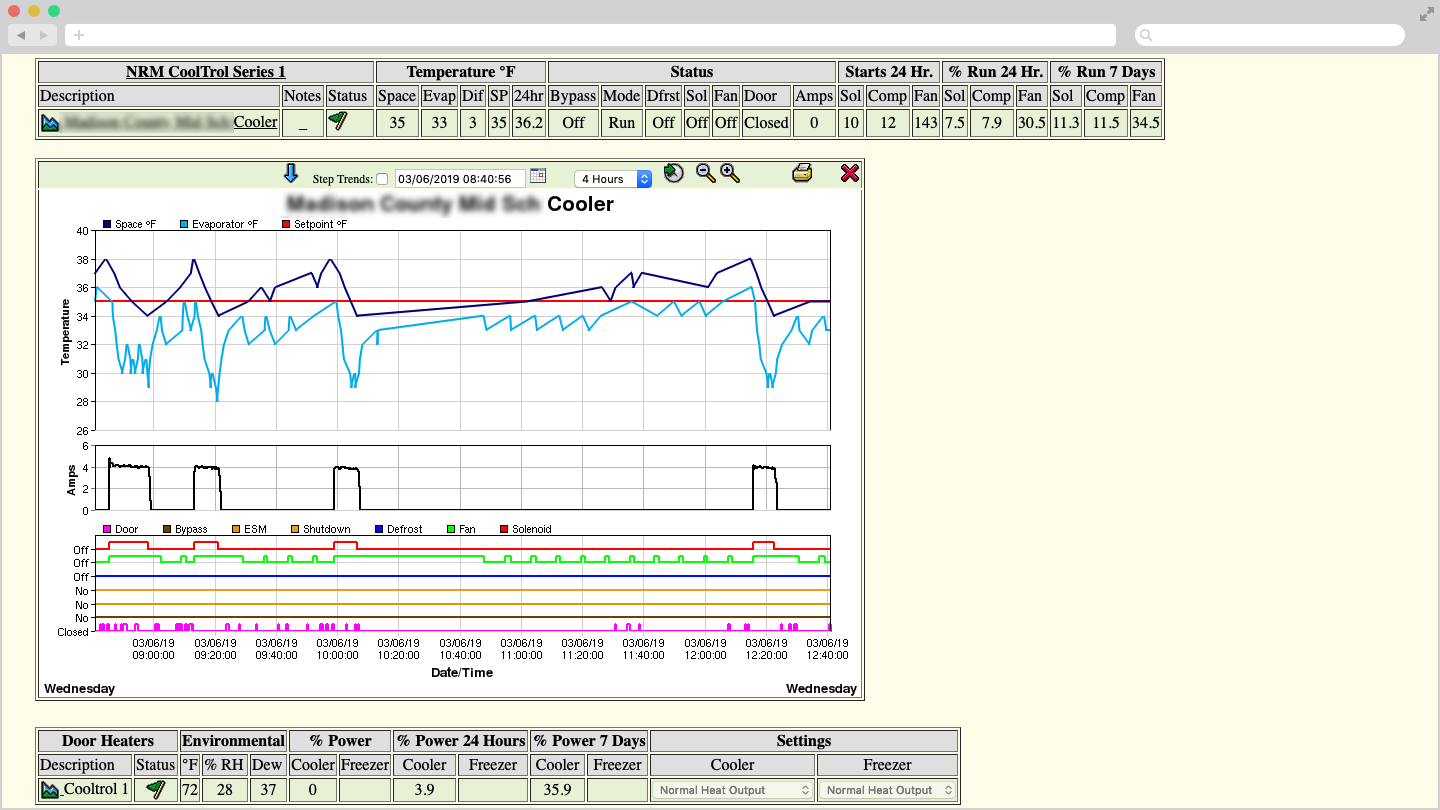

For example, a business with multiple walk-in coolers and freezers that store perishable product will require consistent temperature tracking and confirmation. If this is a large facility, or a situation in which the cold rooms are spread across multiple locations (like on a university campus), this task could require a lot of your time. Saying nothing for the fact that we humans are prone to error—we sometimes rush through tasks, we can misread a number, and we can even skip or forget about a task completely. By removing the burden from your workforce, that time can be rerouted to another facet of the business that could use the extra attention. You will also have the exact data exactly when you need it, with no mistakes.

The same theory can be applied to regular HVAC systems and lighting. With a controls or automation tool, room temperatures and overhead illumination can operate on a scheduled basis, occupancy status, or one of several other triggers. No longer rely on the last person out of the building to ensure all lights have been turned off or the thermostat has been set back.

Visibility

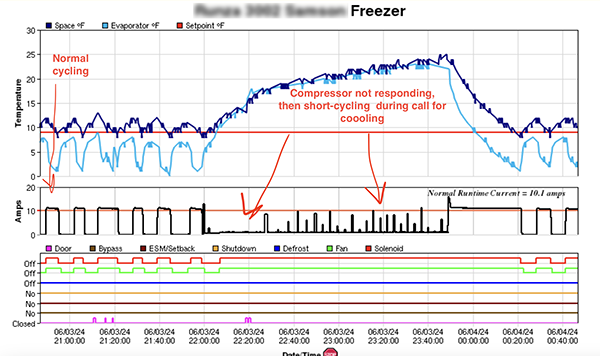

With interconnected technologies, and their constant stream of data, we gain better insight and more clarity into exactly how our systems are running. This provides a number of benefits.

For starters, it allows us to locate areas of operations in which improvements can be made. In thinking of commercial HVAC and refrigeration systems, this equipment is all ready producing valuable data; we’re just not looking at it. Jerry Huson, an engineer at Bosch, said companies are beginning to understand that the data is there and they simply need to access it. Think variable frequency drives, these already give a little insight into how the refrigeration is working but without the cloud, the information is not available on-demand, so to speak. The lack of a cloud-based system, one which is equipped with a user-friendly interface or easy-to-read dashboard, also means that the data is nothing more than a raw data dump, and that can be overwhelming for a person to try and sift through.

“The challenge is to provide meaningful insight into the building’s performance. If the manager has to access a dozen platforms and analyzes all the data herself, IoT can lose its usefulness. Clearly, it’s not good enough to give your customers a ‘data dump’ and let them figure out which data are useful and which are irrelevant.”

Energy Efficiency

One of the leading reasons for a controls and automation solution—if not the leading reason for many business owners and facilities managers—is the efficiency gained in both the equipment and operations.

As mentioned earlier, businesses gain operational efficiency by removing repeatable, menial tasks from their employees and allowing those employees to focus their time and efforts on more productive endeavors.

But you can also gain equipment efficiencies that will not only prolong their lifespans (by working less and by working smarter) but in some cases can save you money. Sticking with commercial refrigeration in this scenario, the potential energy savings are actually huge. Consider this: your walk-in cooler or freezer, with no controls or automation tools in place, is operating at 100% of its capacity. And why wouldn’t it? The refrigeration system was designed to be able to handle a full load during the hottest day of the year, and with no inherent means of knowing when that actually is, it’s operating as if those conditions are present 24/7. Which of course they’re not. Some controls and automation solutions on the market can cut the refrigeration system’s energy consumption in half.

The same practices can be applied to lighting, heating, and air cooling. Empty rooms—or buildings, for that matter—no longer need to be illuminated, heated, or cooled.

“UTC Climate, Controls & Security recently opened its UTC Center for Intelligent Buildings in Palm Beach Gardens, Florida, to showcase a variety of new products enabled by technology convergence and the IoT. One example is demand-based ventilation, where ventilation rate within a controlled space can be adjusted based on the number of cellphones (hence, the number of people) within that space.

‘With this approach, we get a gain in reported occupant comfort, as well as energy savings of approximately 14 percent,’ Chris Opie, vice president, platform management, reported.”