Optimization Solutions for

Walk-in Coolers and Freezers

It’s important that your walk-in cooler or freezer maintains its desired temperatures at all times to keep your product cold and safe. But that doesn’t require the entire system to be running at 100% every day of the year to do so.

Deciding to enhance your refrigeration should be a no-brainer. NRM is here to help make it easy.

Whether you’re storing cold soft drinks or beer, or fresh food that needs to stay at specific temperatures, your walk-in cooler is likely the lifeblood of your business. That said, if you’re not a technician yourself, it’s also likely you try to interact with your refrigeration as little as possible.

“If it’s running, it’s fine,” right?

But if it’s not running at its best, it could be wasting your hard-earned profits in excessive energy costs. It could also be jeopardizing the very product it’s meant to keep safe if unseen issues are forcing the system’s components to operate needlessly. Much like with a car, improper operation for too long could lead to a catastrophic failure, which is the last thing your business needs.

Did you know your walk-in is sized to withstand the single hottest day of the year?

That means some components are operating just as hard in the middle of January as they are in the middle of July.

By optimizing your system so it operates based on need instead of default manufacturer settings, you could prevent wasting real dollars, better protect your inventory, and extend the life of the equipment.

Most common places we find upgrade opportunities:

Evaporator Fan Operation

Evaporator Fan Motors

As most evaporator fans currently operate 100% of the time, the older, inefficient motors are continuously generating and rejecting heat into the cold space. New EC Motor technology are upgrades that drastically reduce the amount of heat created by over 60%, as well as improve overall performance.

Anti-Sweat Door Heaters

Novelty Cooler Runtimes

If you have soft drinks coolers, CoolTrol can schedule them to be off while your business is closed, saving 100% energy during off-hours.

Evaporator Coil Defrost

In-Cooler Lighting Upgrades

Not only reduce energy consumption by upgrading from old, fluorescent lamps to LED, but improve your product display with a cooler, brighter appearance. If applicable, upgrades can include overhead in-cooler lamps as well as door-lined lamps for reach-in product coolers.

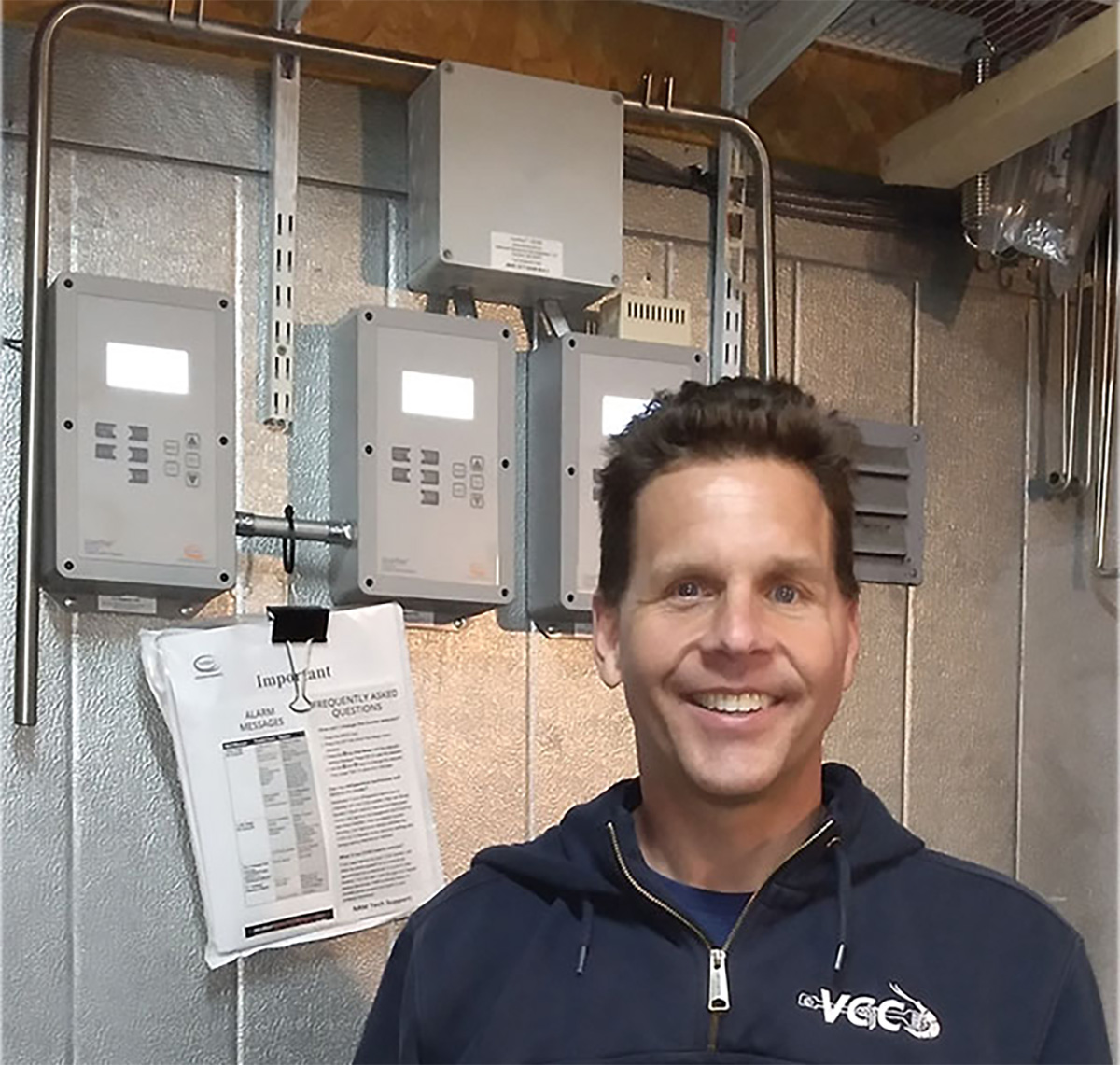

"I’m extremely happy with NRM’s controls and would recommend them to any other business owner on the island that has walk-in coolers. Brian, their installer, was very helpful throughout the whole process and showed me how I would be saving energy. I’ve had the controls for 14 years, and look forward to another 14 of saving money."

— John Averill, Owner

The quickest way to discover if your facility can benefit from our solution is to request a callback:

With some preliminary information about your business, such as current facility operations, energy costs, and most importantly your optimization goals, we can give you a general idea of how we may be able to help.

From there, we’ll decide together the next best step to take. It could be a full, no-obligation refrigeration assessment to identify your actual opportunities, or it could be checking with your utility provider if they offer any incentives for energy-efficiency projects.

CoolTrol® is the backbone of every customized, turnkey solution.

It's more than a "new" thermostat. CoolTrol gives you full control over the operation of your refrigeration system — from bypass features to one-button defrost to temp. settings on the fly, to automated temperature tracking, and more — while also providing long-term "set it and forget" energy savings.

It couldn't be easier to get.

STEP 1.

System Assessment

An NRM specialist conducts a thorough assessment of your refrigerated space, noting everything from current runtimes, total number of compressors and evaporator fan sets, hardware components used, and more. These findings, along with a copy of your commercial electric bill and a sketch of your cold space, are then sent off to NRM engineers to generate your analysis.

STEP 2.

Energy Analysis

Next, NRM engineers analyze the data from the assessment. They calculate how many kilowatt hours can likely be reduced from your energy consumption through both reducing runtimes and adding high-efficiency hardware, and in turn, how much money you could potentially save on your electric bill. All calculations can be measured and verified by observing new runtimes.

STEP 3.

Incentives Application

Following the analysis, NRM applies for the any eligible utility incentives on your behalf. In some cases the utility may offer funds only for certain measures, and in other cases, they offer incentives for the entire refrigeration solution. In addition, some programs offer on-bill financing for zero out-of-pocket cost. NRM works to secure every dollar available for your project.

STEP 4.

Project Proposal

Once all the info is compiled, NRM presents the project scope to you, and any necessary partners, for your approval. It includes measures to be implemented, and long-term energy savings projections. NRM is also happy to explain the project to any additional staff who will be impacted—such as your refrigeration technician, store manager, or Facilities Director.

STEP 5.

Project Approval

After reviewing the proposal, the next step is approving both the measures and cost of project. Once approved, NRM works with you to schedule the installation at a time most convenient for you. NRM’s measures and upgrades are typically implemented with zero disruption to your normal business hours, and is completed by licensed professionals.

STEP 6.

Retrofit Installation

When the installation is complete, NRM provides training for its controls as well as offering 24/7 tech support. But most importantly, all that’s left to do is enjoy the long-term benefits of your new refrigeration management system. Set-it-and-forget-it smart controls deliver energy savings, and the hardware upgrades extend the life of your equipment through less wear and tear.

Upgrades for your refrigeration system may be eligible for generous incentives from your utility provider that cover 50-100% of the project cost.

But incentive dollars are limited, so act now!

Frequently Asked Questions

In an unsafe manner, yes. But with NRM’s solution, it is perfectly safe. Implemented in over 50,000 systems to-date, the new controls keep fans running when refrigeration is ON and only cycles them OFF and whenever refrigeration is OFF. Every running fan motor generates heat and the new system run time when air movement is not necessary. Why keep the heaters running once temperature set point is reached?

NRM has earned the utility’s trust and confidence, which is the greatest guarantee we can offer. In some programs, NRM has been providing solutions since 1997 with the local utility company’s backing. We would not continue to win these contracts year over year if we didn’t produce deliver the projected savings.

Most states have adopted laws to get citizens and companies to use less energy as it is more economical to encourage consumers to use less energy through incentives than to build a new power plant which no one wants near them. Utilities are tasked with collecting a fee on your utility bill based on usage. It may be a line item shown as “public benefit charge” or “energy conservation charge”. This money accumulates and is used to fund the incentives that pay for energy efficiency optimizations. Since it is available for all ratepayers, it is a great way to fund energy efficiency programs that give capacity back to the electrical grid while also reducing your commercial electric bill. So it’s a smart investment to participate in the programs and to take advantage of the incentives to get some of your money back through upgrades to your own equipment. The money isn’t free, but it will contribute toward qualified energy efficiency projects. It’s a great way to make a difference to your bottom line.

It really depends on how much energy a project can save… just think of it as the utility buying capacity from you to prevent overtaxing the energy grid. The power you save now becomes available to new customers. To find out what you can get, we recommend a no cost assessment of your current system that will enable us to calculate savings that we then present to your utility company who allots the amount they will pay for your capacity. If your systems already are considered partially or totally energy efficient, there may be little or no opportunity for reducing energy or qualifying for an incentive.

Success Stories

MD Food Bank

Aeronaut Brewery

Tigers Express

Vineyard Cash & Carry

Shop N' Bag Chain

Salerno's Seafood

Reeds Ferry Market

Gas Station Chain

"NRM has been outstanding through this whole program. Your technicians were very professional, and during the last project, even took the time to answer questions from my refrigeration guy so he could properly interact with the controls moving forward. And the energy savings help everyone’s bottom line. If the utility companies can’t find new ways to generate electricity, our costs are going to go up substantially, so this is a way we all can help."

— Bruce Reamer, Owner